cbq2bn

Chairman

The Zephyr - The only way to Travel

Posts: 727

|

Post by cbq2bn on Mar 29, 2010 12:36:40 GMT -5

I was wondering,

what is a good way to scratch build a tender chassi?

I have a pair of CB&Q Athearn Genesis tender shells I bought,

and can't find chassies for them, so i was wondering what is the best way to build um from scratch.

I believe these are for smaller steam, like 2-6-2 up to around 2-8-0s

Any thoughts or help guys n gals?,

Thanks in advance

|

|

|

|

Post by icghogger on Mar 29, 2010 14:07:59 GMT -5

My method for a quick brass chassis: cut a piece of brass sheet (.040") to the dimensions of the Genesis shell, solder two pieces of code 100 brass rail to the center (for the center sill), add two more pieces of rail for the side sills. Plate to attach coupler is soldered to the center sill and drilled and tapped for the coupler pocket of your choice. For the connection to the locomotive, drill and tap the .040" plate for a drawbar pin to match the hole in the wireless drawbar of the locomotive.

For a plastic chassis: same method but use .040" styrene sheet for the floor, styrene channel stock for the sills and styrene sheet for the coupler mount. The drawbar pin can be a shouldered screw, with head cut off and held in place with nuts on both sides. If you want to use the styrene tender chassis for power pickup, you will have to use metal bolster screws and hardwire the trucks to the drawbar pin (for the wireless pickup type). It goes that you will have to add weight to the styrene version to get positive contact with rail power.

If you like, I can photograph one I built for you to see one of the methods I used.

|

|

cbq2bn

Chairman

The Zephyr - The only way to Travel

Posts: 727

|

Post by cbq2bn on Mar 29, 2010 14:39:15 GMT -5

Thanks Robert(s), I would really like to see pictures of how you did it, that would be awsume, thanks.

|

|

|

|

Post by icghogger on Mar 30, 2010 12:56:24 GMT -5

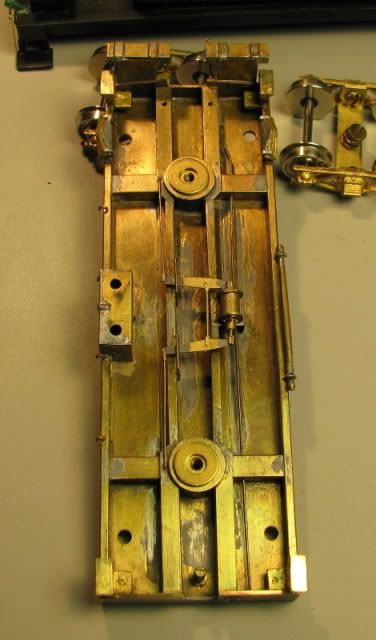

Here are a couple of examples of scratch-built tender frames (chassis) using sheet brass and HO code 100 rail to frame it out. The side sills are in place on this ICRR switcher  Center sills, side sills and crossmembers on a B&O Pacific tender  Code 100 rail sills capped with sheet brass on an MSC Mikado  I am working on an On30 tender in styrene and I will show how I did that one using styrene structural shapes. |

|

cbq2bn

Chairman

The Zephyr - The only way to Travel

Posts: 727

|

Post by cbq2bn on Mar 30, 2010 18:09:10 GMT -5

That is really nice work, I'll send these right over so you can fit me up ;-)

lol,, I think I'll put this project on down the list for later on, It's only 125 miles thr LHS I really like to go to, and they are the only ones who carry any brass stock :-(

|

|

cbq2bn

Chairman

The Zephyr - The only way to Travel

Posts: 727

|

Post by cbq2bn on Apr 6, 2010 22:14:54 GMT -5

I just found out something funny, I was sitting here looking at spectrum 2-8-0 up on the shelf, and got to thinking, didn't Life Like take Athearns design from BB stuff and use in the PK2 locos,

So I got one of these Genesis shells out and took the tender off the Spectrum,

with the Spectrum tender togeter, it looks almost a twin to the ones I have, but, the steps and frame area are on the chassie of the spectrum and not the shell as the Genesis shell it,

but steps and frame look Identical,

A little shaving on the Genesis shell and a little filing, it will fit right on this Spec chassie... Interesting I thought, I'll have pictures of these two in the next day or two to show the sims of them.

|

|