|

|

Post by onequiknova on Jan 3, 2009 0:01:25 GMT -5

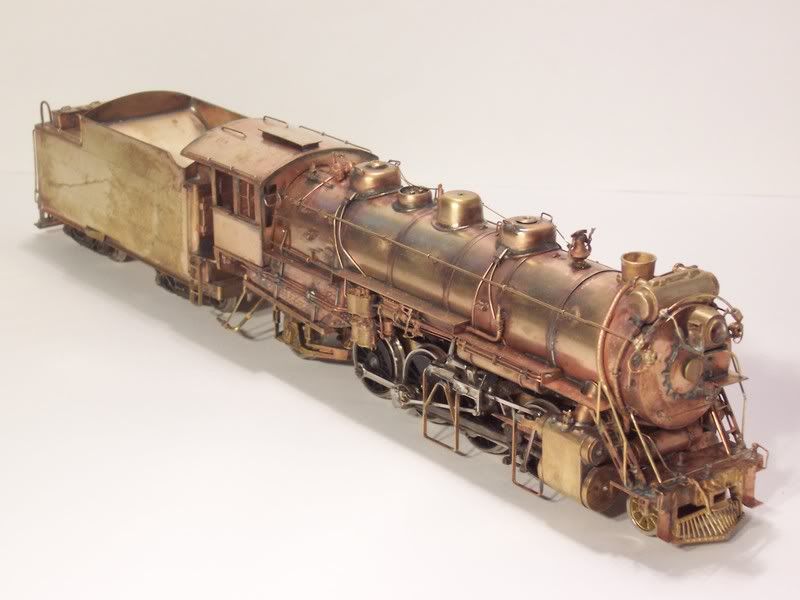

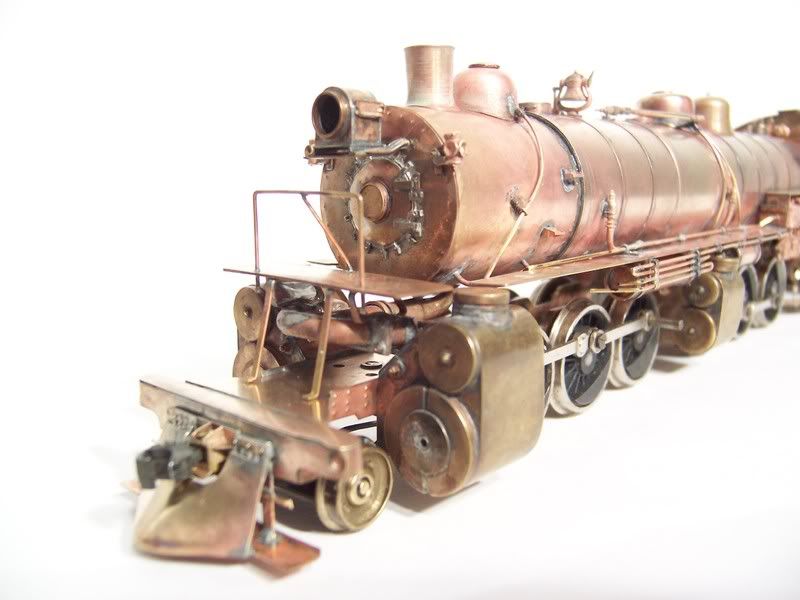

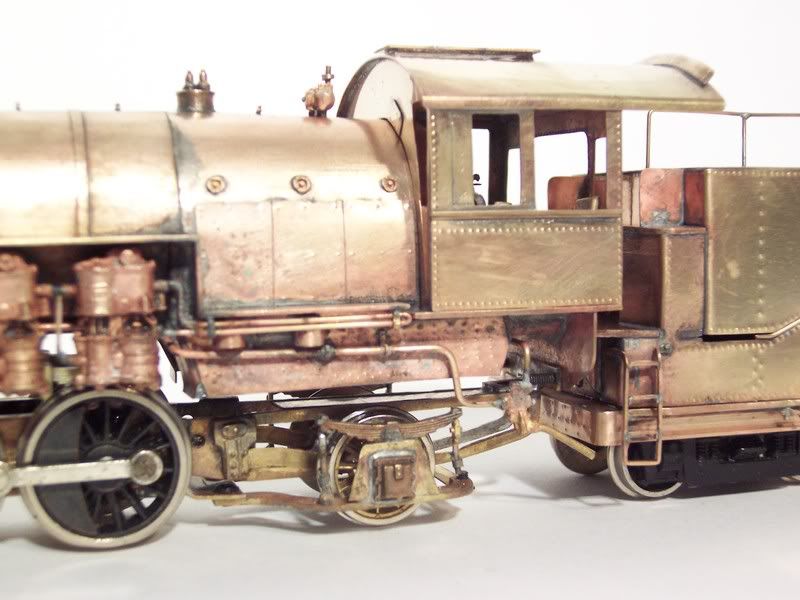

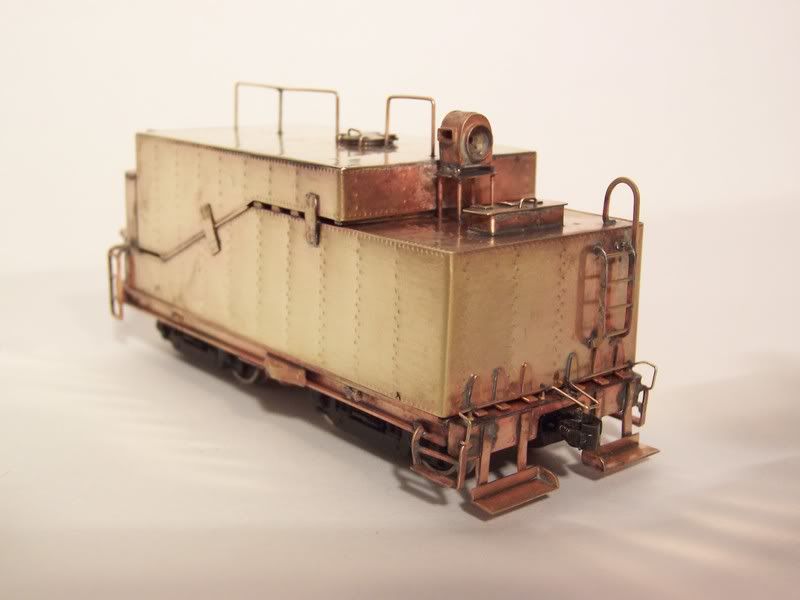

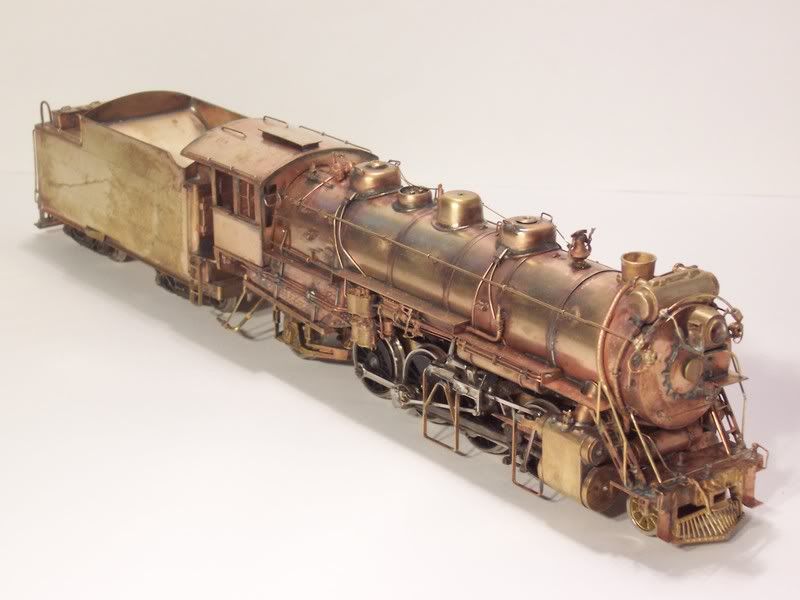

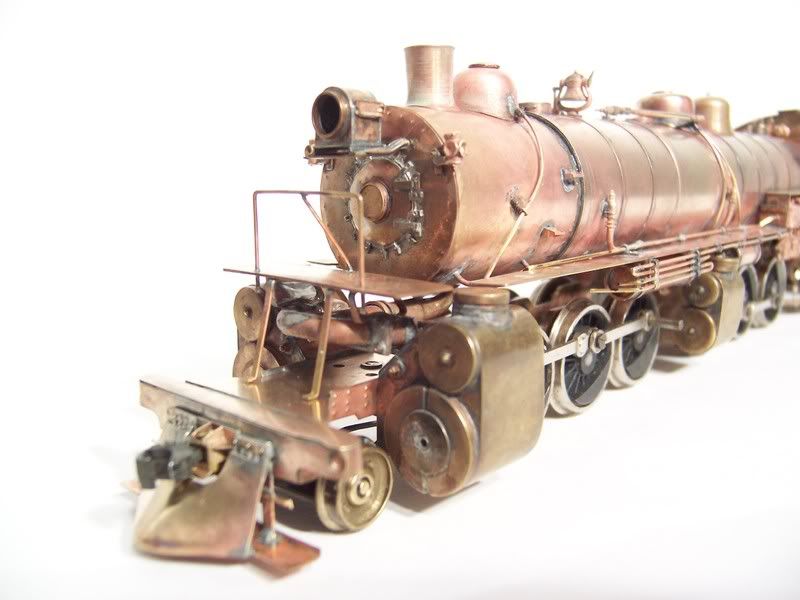

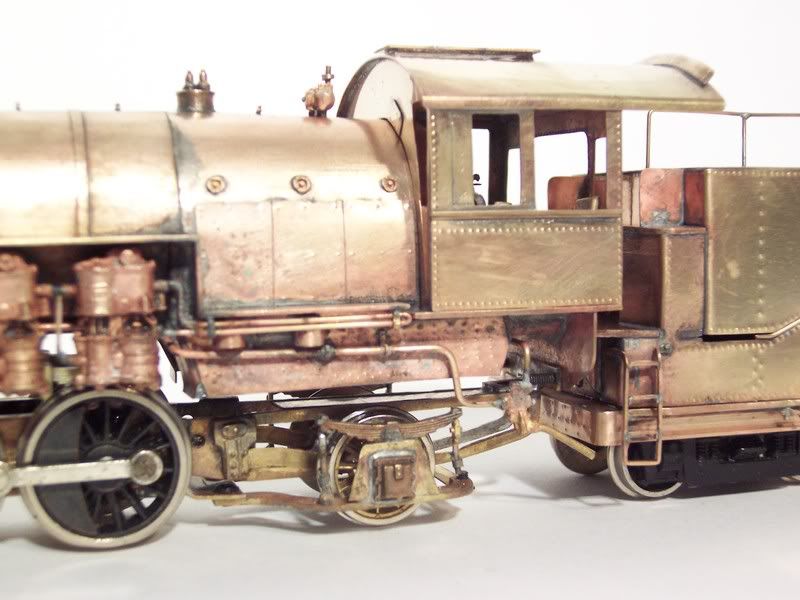

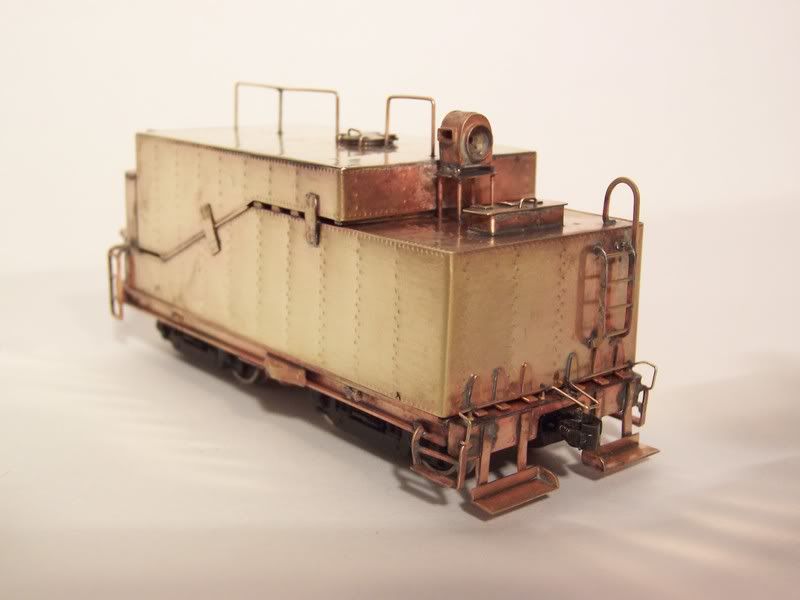

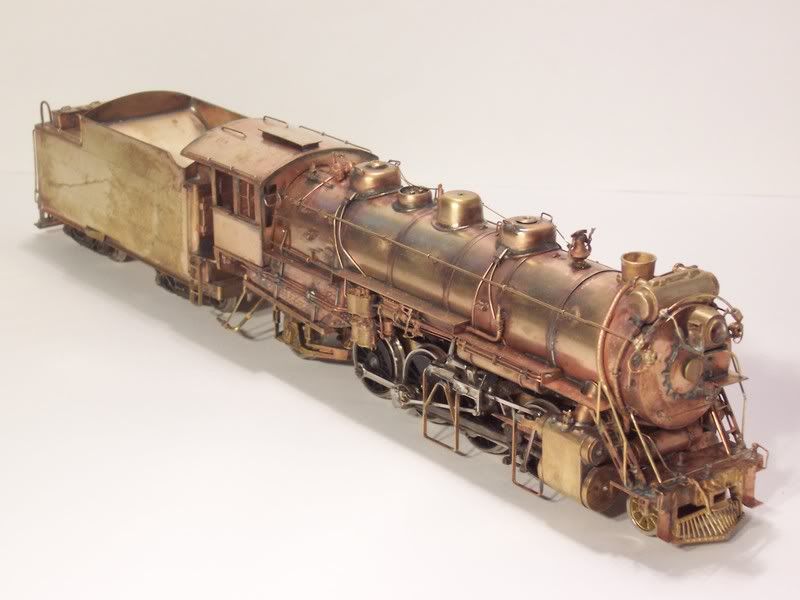

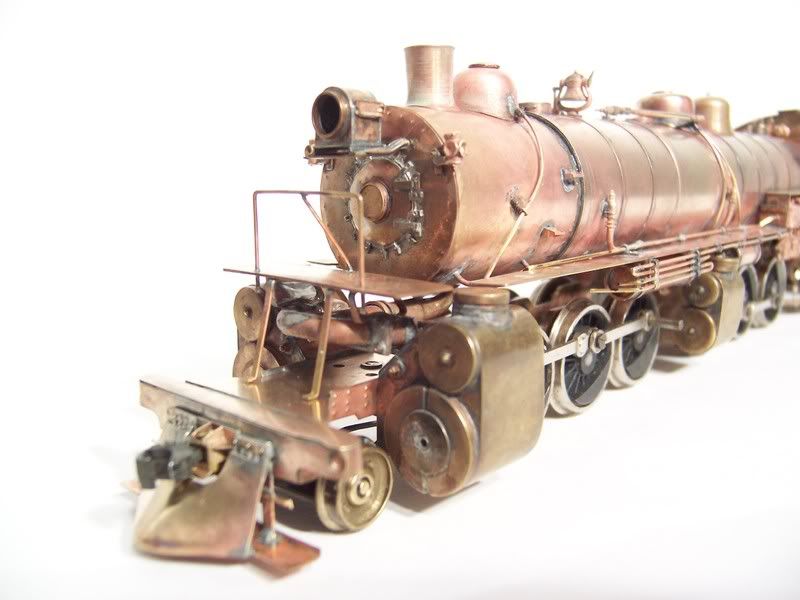

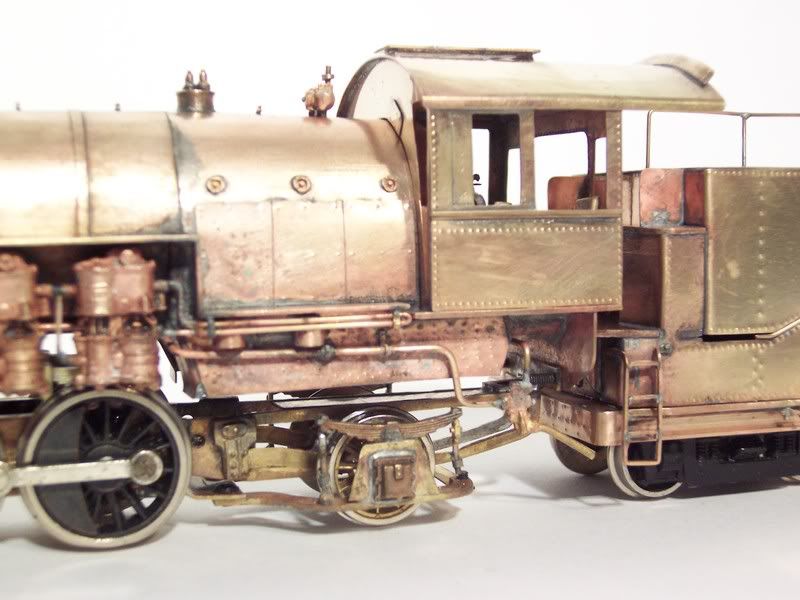

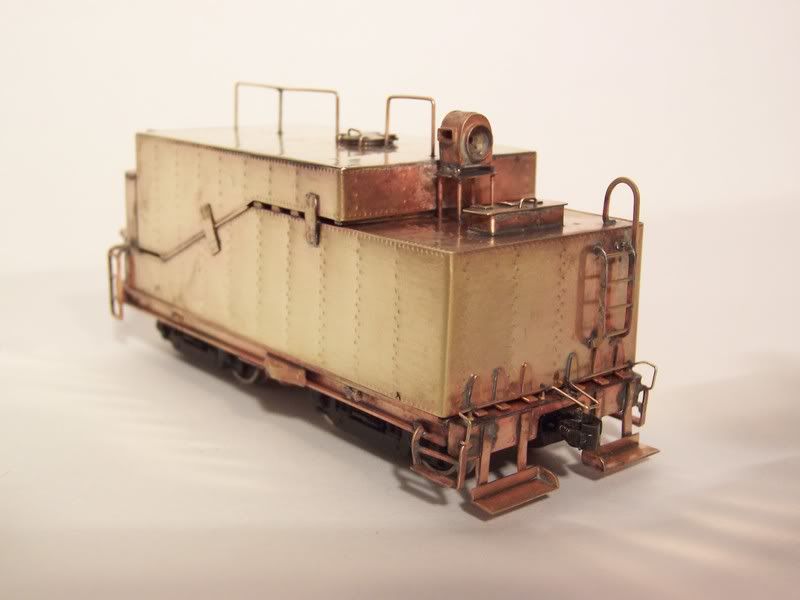

I was asked in one of my other posts to show some of my scratchbuilt steam engines, so here they are. First up is my first attempt at scratchbuilding steam. This engine was built on an old LMB mikado chassis and cylinders that I stretch just behind the rear set of drivers. It is a CB&Q class O2A Mikado. The boiler, cab and tender shell were scrathcbuilt from brass. I learned to solder on this engine and after some practice, was pleased with the results. I do 98% of my soldering with a small butane torch. I used a bunch of Precision scale castings on this engine. [    My second, and currently unfinished project is a CB&Q class T2 2-6-6-2 articulated. This engine is completely scratchbuilt except for the drivers, tender trucks, and a handful of castings. The things I would have used "close enough" castings for on my first engine are scratchbuilt or at least modified to match the prototype on this engine. The problem with this build is that there were only 12 of these beasts built and only a few lasted into the late 40's. So detailed pictures are scarce. I had to wing it on some of the details.     I don't own any special tools like a lathe or mill. I do all my turnings in a electric drill C-clamped to the work bench. I remove the bulk of the turning with a Dremel cut off wheel while the drill is also spinning. I finish up my turnings with files and finaly fine sandpaper. All my rivits are punched by hand with a needle clamped into a pin vice. This can get rather tedious and really cramps up my hand after punching out a complete tender wraper. I cut thin brass sheet (.010 and under) with a strong pair of kitchen sheers. Thicker stock is cut with a Dremel. Either way requires a lot of filing. John |

|

|

|

Post by Randy Earle on Jan 3, 2009 0:12:18 GMT -5

Those are real beauties John, you should be proud.

|

|

sarge

Chairman

Posts: 1,132

|

Post by sarge on Jan 3, 2009 0:49:45 GMT -5

That is some sweet work there. Randy is right, you can definitely be proud of those.   |

|

CIOR

Chairman

Posts: 2,046

|

Post by CIOR on Jan 3, 2009 12:45:58 GMT -5

Wow, that is something. Even showed the wife and she said its a shame you painted it.... LOL

|

|

|

|

Post by onequiknova on Jan 3, 2009 15:25:31 GMT -5

Thanks guys. Wow, that is something. Even showed the wife and she said its a shame you painted it.... LOL I've been told that before, but to me its not finished until its painted and a coat of grime applied. John |

|

CIOR

Chairman

Posts: 2,046

|

Post by CIOR on Jan 3, 2009 15:39:09 GMT -5

John, even though she has been around the hobby for a while now, she didn't know much about brass engines. I guess she had never seen a pure brasser before. I then explained to her that there is a group of collectors that just clear coat the brass and put it on shelves. She liked that idea.

It does look good and your work is good also!

Matt

|

|

|

|

Post by Matthew on Jan 4, 2009 5:39:21 GMT -5

This is mind boggling!

Having turned a few things on a lathe, not to mention fabricated and silver soldered some items in the past, I am amazed at what you have the patience to achieve, particularly with the tools you have described.

Absolutely outstanding.

Matthew

|

|

kcs1967

Chairman

SWLA-SETX PINE SCENTED

Posts: 1,726

|

Post by kcs1967 on Jan 15, 2010 19:58:04 GMT -5

Wow, wonderfully amazing work.

|

|

|

|

Post by rdg5310 on Jan 15, 2010 22:27:21 GMT -5

Building brass steamers is a dying art. The most soldering I done to brass was the repairs on customer engines in the past. That tended to be a real pain in the butt crack. I'm a fan, great work!  |

|

|

|

Post by icghogger on Jan 18, 2010 11:55:14 GMT -5

GREAT Job, John, exceptional detail work!! Thanks for sharing!!

|

|

|

|

Post by romcat on Jan 6, 2012 22:03:49 GMT -5

John:

Lovely work. Certainly what I want to be doing in several years. Have some great scratchbuilding articles from the 60's and 60's.

Do you have a pic(s) of your clamped drill setup and how do you control the speed?

-Gareth

|

|

|

|

Post by John on Jan 7, 2012 16:13:16 GMT -5

Incredible work. Simply incredible.

|

|

|

|

Post by tamaman on Jan 18, 2012 10:30:16 GMT -5

Now thats talent! Nice work John.

|

|

|

|

Post by CentralVermontGuy on Jan 19, 2012 13:16:49 GMT -5

Excellent work John, please keep us posted!

|

|

|

|

Post by onequiknova on Mar 25, 2012 11:59:01 GMT -5

Thanks guys. I just noticed this. I don't check this section very often. Unfortunately I haven't gotten much more done on the articulated except for building the valve gear on the front set of drivers. I'm having trouble figuring out how to power the front set of drivers. I don't have room for the typical Hi/Lo gear box arrangement. I need to go with two low, non idler boxes, but I haven't found the right size yet.  The valve gear started out as a brass kit for a MDC 0-6-0, but every piece has to be modified to fit this engine. Unlike most brass steam I've seen, the slide valve moves in time with the piston instead of being in a neutral position. I don't have pictures of the drill set up, but the drill has its own simple speed controller. You lock the trigger, then turn a dial on the trigger to vary the speed. |

|

jast

Probationary Member

Posts: 6

|

Post by jast on Mar 25, 2012 19:54:30 GMT -5

This is very inspiring work. I am also scratch building an engine. In my case it is a CN J7 Pacific. It is based on an old Mantua frame and drivers. The rest will be assembled from parts and scratch. I started by restoring a sunset Mikado into a CN Mikado. It was rewarding so now I want to go a bit further. Thanks for the great pictures and superb work.

Julian

|

|

|

|

Post by analogbeatmaker on Mar 30, 2012 13:41:56 GMT -5

Wow...that is really amazing! I really like it after the paint and weathering. You did as good of a job on the finish as the build. Excellent!!

|

|

|

|

Post by malcolmcelyn on Mar 29, 2014 9:18:51 GMT -5

Sorry to re-open an old thread.

Being a relative newcomer to the US scene, I'm not too sure where to look for parts, like chimneys, domes, sandboxes, Westinghouse pumps and similar.

Can anyone point me in the right direction? HO, USRA-types, Consolidation and Light Mikado.

Also, John, fabulous, beautiful and any other superlative you can think of! Can't believe that was your first model. Awesome!

I've managed to read quite a bit about brass (and styrene) body construction and feel comfortable with construction as long as I have a pile of detail parts to use. What I can't seem to

find much on is chassis construction. I'm familiar with UK-style plate-frame chassis construction, but not US-style bar frames. Whilst using an r-t-r chassis is a good idea for a first attempt, I'm really

Interested in scratch building one. Do you have any photos of your chassis and running gear? What websites did you use for information or inspiration? Any steam versions of the DD out there?

Thanks, Malcolm.

|

|

|

|

Post by Randy Earle on Mar 29, 2014 21:29:05 GMT -5

Bowser used to have a slew of parts for detailing steam.

|

|

|

|

Post by malcolmcelyn on Mar 30, 2014 3:44:46 GMT -5

Thanks Randy. Via the Bowser site I've found CalScale. Also, Cary and some other bits and pieces.

|

|